Production Process

We listen to our customers' needs and fully discuss specifications for metal filters. Through examining each issue, such as filter usage, built-in location, and for mass-production, we select the materials and configuration best suited for each client's individual needs. Our own dies (we own over 150 dies) can be used for your orders, and we can also offer you configuration, dimension and mesh at a reasonable cost.

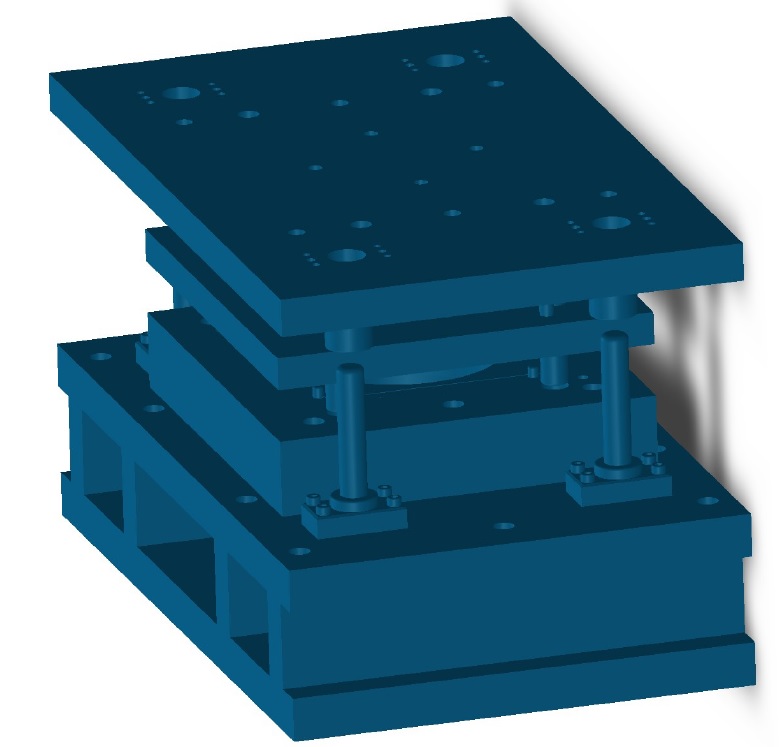

Die making technology is essential to the manufacture of metal filters. Our dies are produced through metal cutting work using CNC lathes,Machining center machine,CNC wire cut and Grinding machine which are then finished off by our highly skilled technician and engineer. Our abundance of knowledge accumulated over years reflects into our die machining, enabling us to achieve the high quality and high-volume production.

The cutting process.We also can only cutting mesh depend on customer requirements.The customer able to assembly or produced in their plant.Our monthly production capacity is approximately five million units. We can handle a wide range of materials and configurations, from filters in the size of rice grains to smooth-as-silk screen meshes. From 1 piece product orders to high-volume orders, we can deliver the products even the deadlines are so short.

We are qualified by ISO9001:2015 certification and established our own quality management system. Before the production starts, we follow the "initial production control" on all our products to ensure quality assurance.That ensures quality and prevents producing defective products. After finishing the manufacturing, we check the quality including product test specifications, following quality control process charts, test charts and test reports to ensure delivering only trustworthy products to the customers.